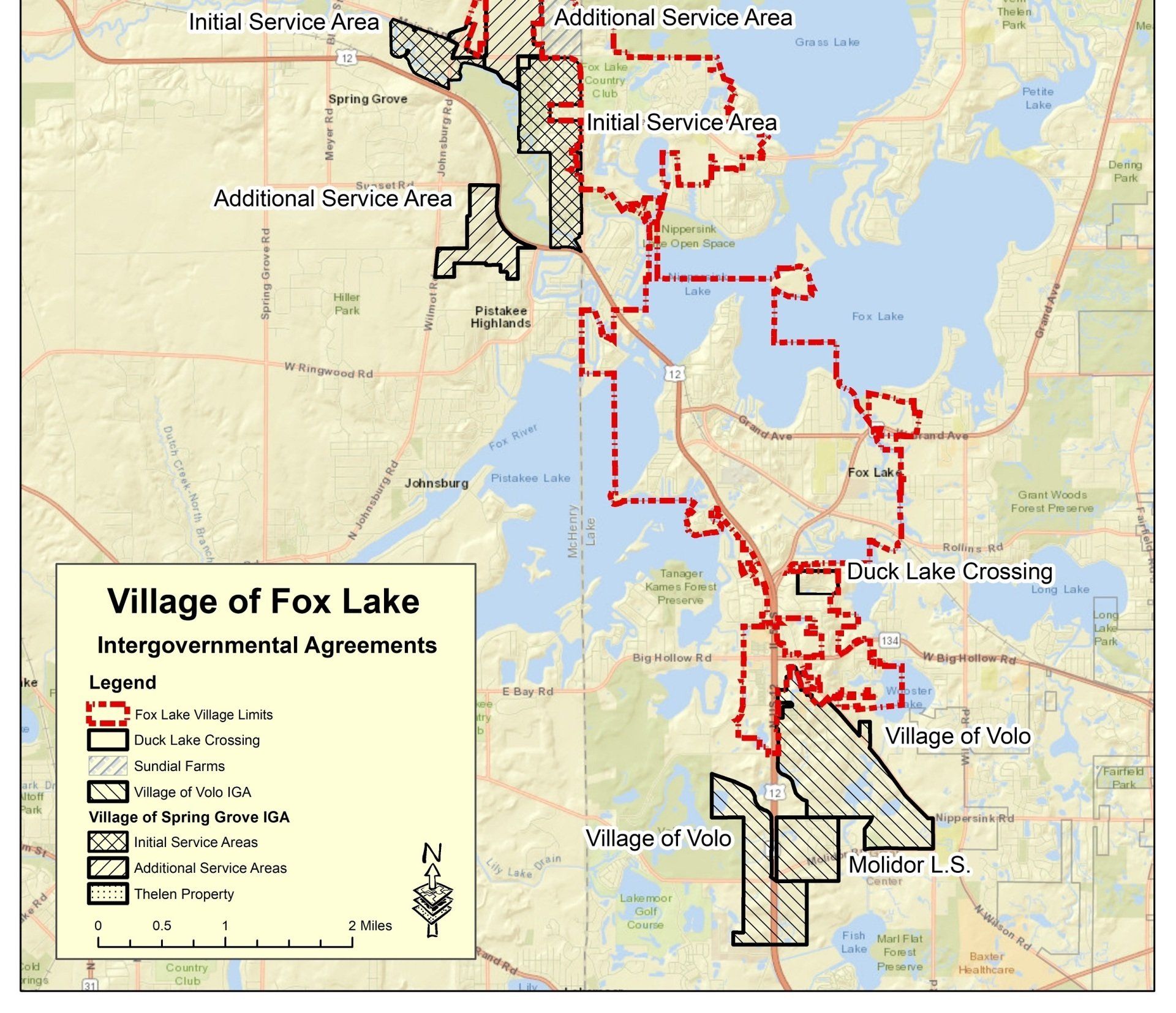

The Village of Fox Lake engaged Trotter and Associates, Inc. to work with a sign design firm, obtain permits, and provide construction observation for the fabrication and installation of wayfinding signs throughout the Village. The project also included removing and replacing Village of Fox Lake signs with new monument signs. These monument signs incorporated the stone base and Village logo as seen throughout other structures constructed within the Village over recent years. The project involved permitting three separate DOTs which included: IDOT, Lake County, and McHenry County. In total, 19 signs were installed, and more are slated for construction in 2025.